MELT POINT DETERMINATION

MPM - H3 semi-automatic & MPM - HV3 semi-/fully automatic

With the new series 3, you can determine the melt points of powdery

substances up to 360 °C with the capillary method.

Depending on device version, the melt point will be determined visually by observation (max. 3 capillaries) of the sample through a magnifying glass in the MPM-H3 model. The MPM-HV3 model also permits visual melt point determination (1 capillary) or automatic measurement.

One great difference between the predecessor models of the H2 series and the H3 series is in documentation. This has become indispensable in the scope of QMS management.

Both device versions have a USB interface that permits generating a

measuring protocol on your computer as a PDF file that corresponds to the demands of a contemporary QMS documentation.

A new, larger display in connection with a height-adjustable table stand ensures relaxed work.

The new indirect mirror and glare-free lighting of the substance for visual measurement through the magnifying glass protects the user‘s eyes.

QMS Management

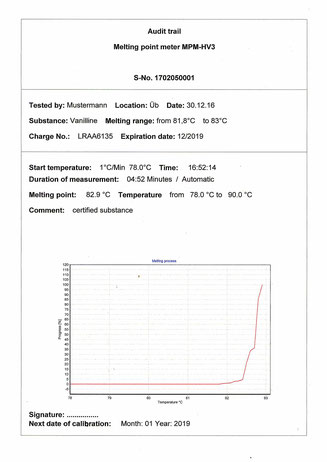

1. The log automatically has the device version with the serial numberprinted on to ensure tracking to the respective meter.

2. To support the QMS, the measuring minutes indicate the next due calibration date of the device and thus ensure its monitoring.

3. For a log to be printed, mandatory fields such as name, location and data for the substance must be entered. This ensures assignment to the tested substance and the testing person.

4. The mandatory input of the substance designation, the melt range (from/to °C) and the corresponding batch number and best-before date of the substance warrants assignment of the measuring log to the substance.

5. The date and time of the measurement are automatically recorded in the log.

6. After completing the measurement in the 1 ÅãC/Min mode, the measuring duration in minutes and the temperature measuring range (starting temperature and end temperature) in ÅãC with the determined melt point are saved or printed automatically and displayed.

7. In the MPM-HV3 version, an additional chart with the transparency curve of the substance by light measurement is generated in the log additionally for the automatic measurement.

8. The input field for comments permits recording individual and important comments on the measuring log in addition to the measurement.

9. Up to three measurements are saved in the device. Then, you will be asked to either print the logs or delete them.

10. By the note „Signature“ at the end of the log, the lab worker will be asked to confirm the measuring log by personal signature.

MODEL MPM - H3 AND HV3

Technical data

Mains voltage 88 – 264 V / AC 0.8 A

Heating output 12 V / DC 25 VA

Protection class IP20

Measuring range to 360 °C

Measuring accuracy +/- 0.4 °C

Reproducibility +/- 0.3 °C

Magnifying glass 20 dioptre / 5-fold

Capillary outside x inside x length 1.45 x 1.0 x 80 mm

unilaterally closed.

Dimensions housing W x H x D 32 cm x 26 cm x 6.5 cm

Dimensions display W x H 8.5 cm x 5.5 cm

Weight unit 4.0 kg

Weight stand 2.8 kg

Height adjustment from table to middle of magnifying glass:

36 cm to 46 cm

Weight unit 4.0 kg

Weight stand 2.8 kg

Height adjustment from table to middle of magnifying glass:

36 cm to 46 cm

Accessories

1 x mains cable

1 x safety hood

1 x 100 capillaries

1 x USB cable

1 x software as a CD or USB stick

1 x operating instructions

TEST LOG

Melt point determination unit MPM-HV3 / MPM-H3 without chart

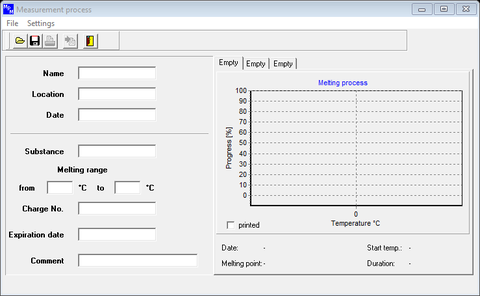

Software

Input screen

Schorpp Gerätetechnik

Andreas Schorpp

Rosenhag 4

D-88662 Überlingen

Tel +49(0)7551-948310

Fax +49(0)7551-948311

Schorpp Device Technology

Andreas Schorpp

Rosenhag 4

Germany-88662 Überlingen

Phone +49(0)7551-948310

Telefax +49(0)7551-948311

Schorpp la technologie

Andreas Schorpp

Rosenhag 4

Allemagne-88662 Überlingen

T.l.phone +49(0)7551-948310

T.l.copie +49(0)7551-948311

Schorpp tecnología

Andreas Schorpp

Rosenhag 4

Alemania-88662 Überlingen

Teléfono +49(0)7551-948310

Fax +49(0)7551-948311

Schorpp П ТЕХНОЛОГИЯ

Rosenhag 4

Иберлинген-88662 Überlingen

Телефон +49(0)7551-948310

Телефакс +49(0)7551-948311